how to prepare Bar Bending Schedule (B.B.S) of Compound wall

Bar Bending Schedule (B.B.S) is list of Steel Drawing document, which include detail section of Particular Item, in this section you will get such detail as, shape of bars, diameter of bars, length of bars, lap of bars and it also include some General Thumb rules in Bar Bending Schedule but the main part is how to prepare bar bending schedule for construction site.

which data require to prepare Bar bending schedule (B.B.S)

how to calculate Unit weight of steel bars per meter formula (kg/m)

Method 1: – calculate weight of 12 mm bars

Weight (kg/m) = Volume x Density weight = (3.14/4 x d2 (12 mm = 0.012 m) x Density (7850) weight = ((3.14/4) x (0.012 x 0.012) x 7850 Weight = (0.785 x 0.000144 x 7850) = 0.89 kg/m 12 mm Dia weight for 1.00 meter = 0.89 kg/m

Method 2: calculate weight of 12 mm bars

weight = d2/162 weight = (12×12)/162 = 0.89 kg/m 12 mm Dia weight for 1.00 meter = 0.89 kg/

| sr.no | Dia of bar | Weight of bar for 1 m length (kg/m) |

|---|---|---|

| 1 | 8 | 0.39 |

| 2 | 10 | 0.62 |

| 3 | 12 | 0.89 |

| 4 | 16 | 1.58 |

| 5 | 20 | 2.47 |

| 6 | 25 | 3.86 |

| 7 | 28 | 4.84 |

Clear Cover as per IS 456

Footing cover as per IS 456 – 50 mm

Column cover as per IS 456 – 40 mm

Beam cover as per IS 456 – 25 mm

slab cover as per IS 456 – 25 mm

thumb rule for bar bending schedule

thumb rule for column

- every floor one no of lap consider in column.

- not more than 50% bar lapped in one junction.

- Minimum 12 mm diameter use in column.

- Hook for Ring = 10 x diameter

thumb rule for Beam

- Bottom bar lap should be at column junction.

- Top bar lap should be at center of columns.

- Ring Distance as per design drawing.

- Consider 1 no of lap at every 12.00 m

thumb rule for Slab

- Provide Main steel at shorter span and Distribution steel at longer span

- Spacing of main steel is 3D or 300 whichever is more and for Distribution steel 5D or 450 mm whichever is more

- Provide extra top bar as per design drawings.

B.B.S of Compound wall sample excel file

let’s start to prepare Bar bending schedule (B.B.S) of Compound wall.

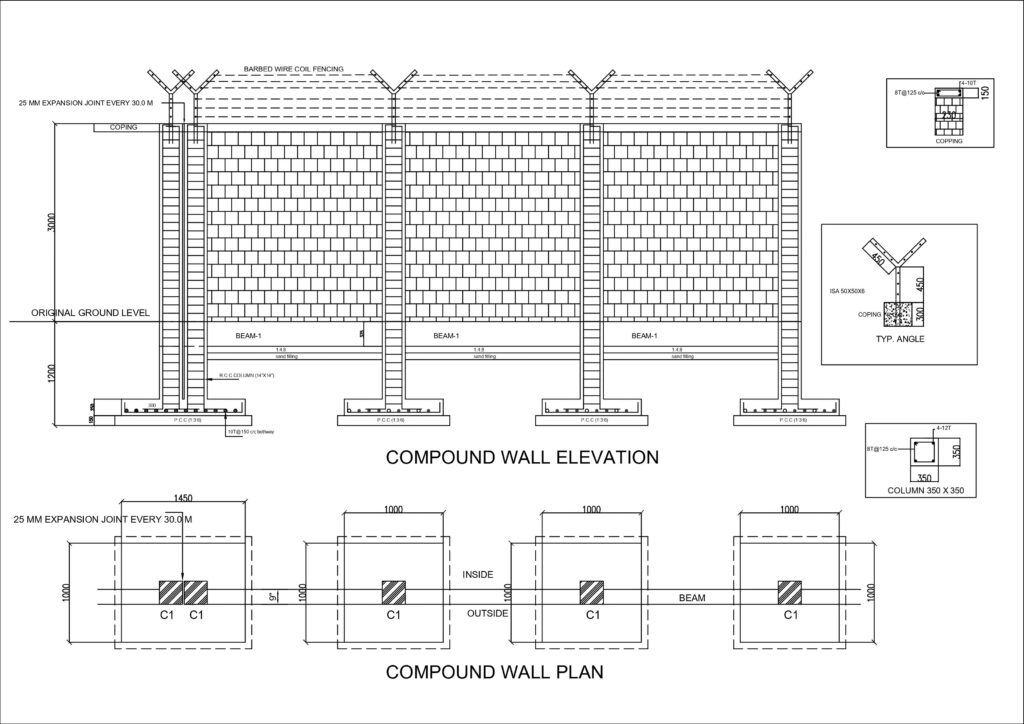

How to find footing Quantity?

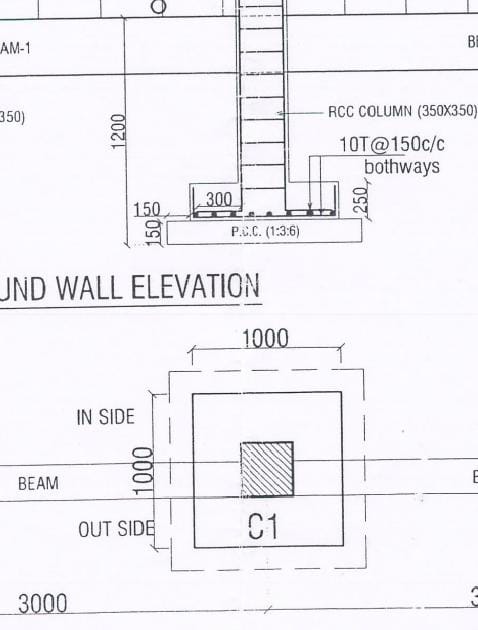

Data- 10T @150 c/c both ways, footing cover 50 mm (0.050 m), 9 no’s of footing

- Footing size (1000 x 1000 x 250 mm)

No of bars in long site and short site same so = 2 x (L- (2 x cover))/150 +1 No of bars = 2 x (1000- (2×50))/150+1 No of bars = 2 x (900/150) +1 No of bars = 2 x 7 (no in one side) = 14 no

Length of cutting bar = (Length- (2 x cover)) + L (both side Length of cutting bar = (1000-(2 x 50)) + (2 x 150) length of cutting bar = 900+300 = 1200 mm = 1.2 m

For Double footing at Expansion joint at every 30 m

2. Footing size =(1450 x 1000 x 250 mm), Steel 10T@150 mm c/c both ways

No of bars in long site = (L- (2 x cover))/150 +1

No of bars = (1450- (2×50))/150+1 No of bars = (1300/150) +1 = 10 no

Length of cutting bar = (Length- (2 x cover)) + L (both side Length of cutting bar = (1000-(2 x 50)) + (2 x 150) length of cutting bar = 900+300 = 1200 mm = 1.2 m

No of bars in short site = (L- (2 x cover))/150 +1 No of bars = (1000- (2×50))/150+1 No of bars = (900/150) +1 = 7 no

Length of cutting bar = (Length- (2 x cover)) + L (both side Length of cutting bar = (1450-(2 x 50)) + (2 x 150) length of cutting bar = 1350+300 = 1650 mm = 1.65 m

| Item no | Items | No | Dia | Length | width | cutting | No of bar | No of bar | Dia | |||

| length | x direction | y direction | 8 | 10 | 12 | 16 | ||||||

| 1 | Footing Quantity | |||||||||||

| single footing | ||||||||||||

| x-direction | 9 | 10 | 1 | 1.2 | 7 | 0 | 75.6 | 0 | 0 | |||

| Y-direction | 9 | 10 | 1 | 1.2 | 7 | 0 | 75.6 | 0 | 0 | |||

| Double footing | ||||||||||||

| x-direction | 1 | 10 | 1 | 1.2 | 7 | 0 | 8.4 | 0 | 0 | |||

| Y-direction | 1 | 10 | 1.45 | 1.65 | 10 | 0 | 16.5 | 0 | 0 | |||

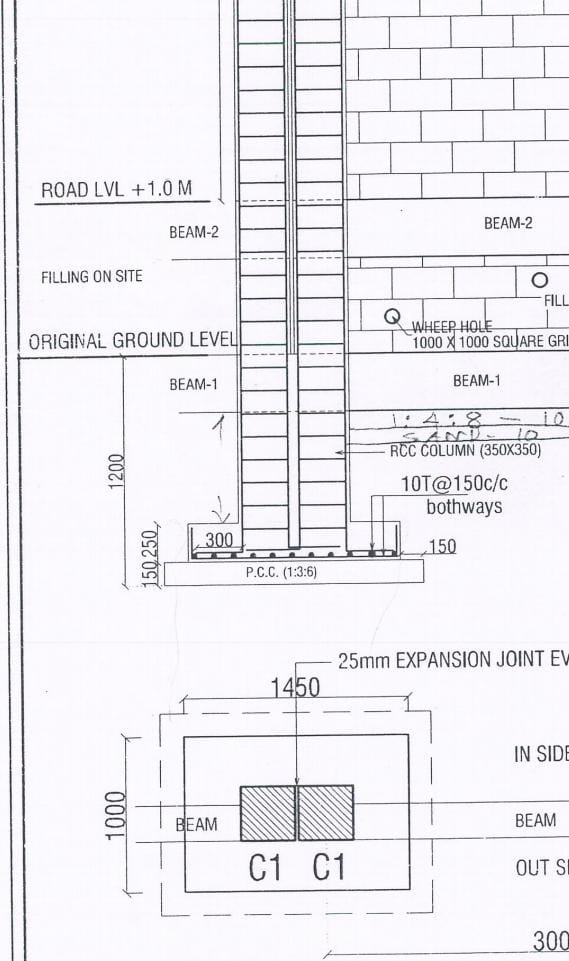

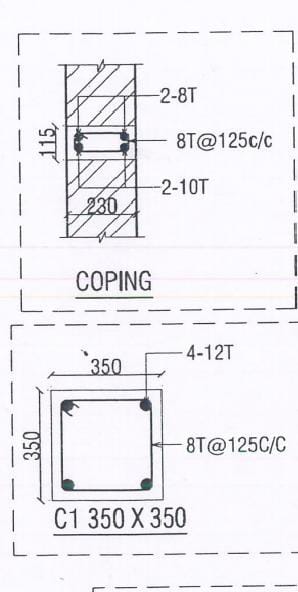

How do you calculate the quantity of steel in column

Given data, Column size = 0.35 x 0.35, steel = 4-12T, Ring= 8T@125 c/c, hook = 10 Dia, height below ground level = 1.2 m, above ground level = 3.0 m, clear cover = 50 mm, Ld=300mm

Height of below ground level = 1.2-0.15 (P.C.C)-0.050 (Bottom cover) + 300 = 1.3 m

no of ring up to ground level = (1.2-0.15)/0.125 +1 = 9.4. say 10 rings

Length of ring= ((L-2 x cover) + (B-2 x cover) + 10xd (hook Length of ring = ((0.35- (2 x 0.040)) + ((0.35 – (2 x 0.040) + (10×8) Length of ring = (0.35-0.08) + (0.35-0.08) + 0.16 = 0.27 + 0.27 + 0.16= 0.7 m

Height of above ground level = 3.00 + 1 lap

No of Ring = 3000/125 +1 = 25 no of ring

| Item no | Items | No | Dia | Length | width | cutting | No of bar | No of bar | Dia | |||

| length | x direction | direction | 8 | 10 | 12 | 16 | ||||||

| 2 | Column Quantity | |||||||||||

| below ground level | ||||||||||||

| Column steel 4-12T (0.35×0.35) | 9 | 12 | 1.3 | 1.3 | 4 | 0 | 0 | 46.8 | 0 | |||

| Ring 8T @ 125 c/c | 9 | 8 | 0.7 | 0.7 | 8 | 52.5 | 0 | 0 | 0 | |||

| above ground level | 9 | 12 | 3.05 | 3.05 | 4 | 0 | 0 | 109.8 | 0 | |||

| Ring above ground level | ||||||||||||

| no of ring = 3.00/0.125+1 | 9 | 8 | 0.7 | 0.7 | 25 | 157.5 | 0 | 0 | 0 | |||

| Add 1 lap 50 x d | 9 | 12 | 0.45 | 0.45 | 4 | 0 | 0 | 16.2 | 0 | |||

how to find steel quantity in beam

| Beam size = (0.230 x 0.375), Bottom- 4-12, Top- 3-10, Ring- 8T@125 c/c, beam length = 30 m, cover-25 mm. Lintel size= (0.230×0.115) bottom-2-10T, top= 2-8T, Ring – 8T@125 c/c |

Length of beam steel = Length – (2 x cover) + (2 x L) Length of beam steel = 30-(2 x 0.025) +(2 x 0.15) Length of beam steel = 30.25 m + 2 lap (take every 12 m 1 lap)

Ring length = (0.230- 2 x 0.025) + (0.375- 2 x 0.025) +0.160 = 0.665 m. No of ring = 3.00 c/c so in to in (3.00-0.35 (column)) = 2.65 m

Lintel

Length of lintel beam = 30-(2 x 0.025) + (2 x 0.050) = 30.05 m. Ring Length = (0.230-2 x 0.025 + (0.115-2 x 0.025) +0.160 = 0.405 m

| Item no | Items | No | Dia | Length | width | cutting | No of bar | No of bar | Dia | |||

| length | x direction | y direction | 8 | 10 | 12 | 16 | ||||||

| 3 | Beam & lintel Quantity | |||||||||||

| Beam | ||||||||||||

| bottom bar – 4-12 | 1 | 12 | 30.2 | 4 | 0 | 0 | 120.8 | 0 | ||||

| Top bar – 3-10 | 1 | 10 | 30.2 | 3 | 0 | 90.6 | 0 | 0 | ||||

| 2 lap (50xd) | 2 | 12 | 0.6 | 2 | 0 | 0 | 2.4 | 0 | ||||

| top bar 2 lap | 2 | 10 | 0.5 | 2 | 0 | 2 | 0 | 0 | ||||

| Ring | 10 | 8 | 0.665 | 0.665 | 22 | 147.63 | 0 | 0 | 0 | |||

| Lintel | ||||||||||||

| bottom bar – 2-10 | 1 | 10 | 30 | 2 | 0 | 60 | 0 | 0 | ||||

| Top bar – 2-8 | 1 | 8 | 30 | 2 | 60 | 0 | 0 | 0 | ||||

| 2 lap for bottom bar | 2 | 10 | 0.5 | 2 | 0 | 2 | 0 | 0 | ||||

| 2 lap for top bar | 2 | 8 | 0.4 | 2 | 1.6 | 0 | 0 | 0 | ||||

| Ring | 10 | 8 | 0.405 | 0.405 | 22 | 89.91 | 0 | 0 | 0 | |||

Total Quantity (footing + column + beam + lintel)

8T = (52.5+157.5+147.6+60+1.6+89.91 = 509.1 x 0.395 (8mm Dia weight) = 201.10 kg. 10T = 75.6+75.6+8.4+16.5+90.6+2+60+2 = 330.7 x 0.617 (10 mm Dia weight) =204.1 kg. 12T = 46.8+109.8+16.2+120.8+2.4 = 296 x 0.89 (12 mm Dia weight) = 263.1 kg. Total weight of steel = 201.10+204.1+263.1 = 668.4 kg